Np-chart

| np-chart | |

|---|---|

| Originally proposed by | Walter A. Shewhart |

| Process observations | |

| Rational subgroup size | n > 1 |

| Measurement type | Number nonconforming per unit |

| Quality characteristic type | Attributes data |

| Underlying distribution | Binomial distribution |

| Performance | |

| Size of shift to detect | ≥ 1.5σ |

| Process variation chart | |

| Not applicable | |

| Process mean chart | |

| |

| Center line | |

| Control limits | |

| Plotted statistic | |

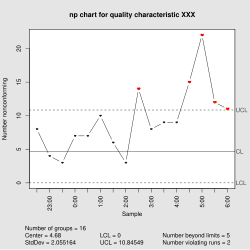

In statistical quality control, the np-chart is a type of control chart used to monitor the number of nonconforming units in a sample. It is an adaptation of the p-chart and used in situations where personnel find it easier to interpret process performance in terms of concrete numbers of units rather than the somewhat more abstract proportion.[1]

The np-chart differs from the p-chart in only the three following aspects:

- The control limits are , where n is the sample size and is the estimate of the long-term process mean established during control-chart setup.

- The number nonconforming (np), rather than the fraction nonconforming (p), is plotted against the control limits.

- The sample size, , is constant.

See also

- p-chart

References

- ^ Montgomery, Douglas (2005). Introduction to Statistical Quality Control. Hoboken, New Jersey: John Wiley & Sons, Inc. p. 279. ISBN 978-0-471-65631-9. OCLC 56729567. Archived from the original on 2008-06-20.